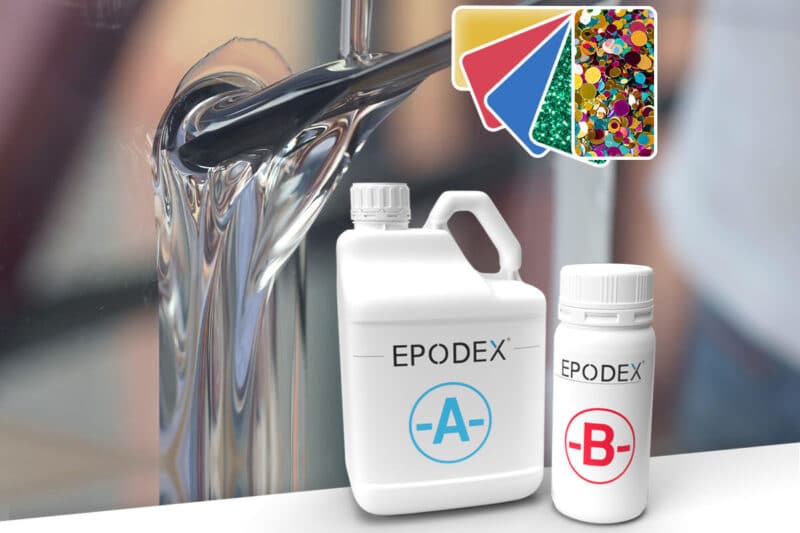

EPODEX Epoxy Resin Alcohol Inks

EPODEX Alcohol Inks are transparent and fast-drying alcohol-based ink colors specifically designed for fluid painting techniques. Create individual color gradients, abstract effects, and surprising shapes with EPODEX Alcohol Inks.

The ink can be used on almost all smooth, non-porous materials. Epoxy resins, synthetic papers (e.g. Yupo paper), glass, metal, ceramics, porcelain, stone or modeling clay are best suited. After drying, the acid-free Alcohol Inks are smudge-proof and waterproof.

Application on epoxy resins

- Mix epoxy resin and hardener 2:1 (e.g. 64oz resin: 32oz hardener).

- Pour the resin-hardener mixture onto the desired surface or into the desired mold. For the typical Alcohol Ink effect (“Petri-Art effect“) we recommend a maximum pouring height of 19/32”.

- Add the colored alcohol ink of your choice to the still liquid resin-hardener mixture and then add the alcohol ink SELENIT WHITE. The inks will react with each other creating a unique pattern. The more white ink drops you add to the colored ink drop, the more pronounced and deeper the effect will be.

- To achieve a full-surface result, you can, for example, place several colored drops next to each other and alternate them with white drops to create a pattern. The more white drops you put on the colored drop, the deeper the colors sink into the resin and the stronger the Alcohol Ink effect is.

- Work with different colored paints for a multicolored result.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely. For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 70°F) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption Volumes

Determine the required amount with the help of our epoxy resin “Epoxy calculator” on this page.

Total Thickness for Floors and Other Surfaces: 1/16”

- Priming with ECO: approx. 1oz/sqft

- Priming with EPOXY PRIMER: approx. 0.65oz/sqft

- Main Layer: approx. 4oz/sqft

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colors may not be uniformly displayed. All information is recommendations based on our experience; without legal obligation.

Reviews

There are no reviews yet.