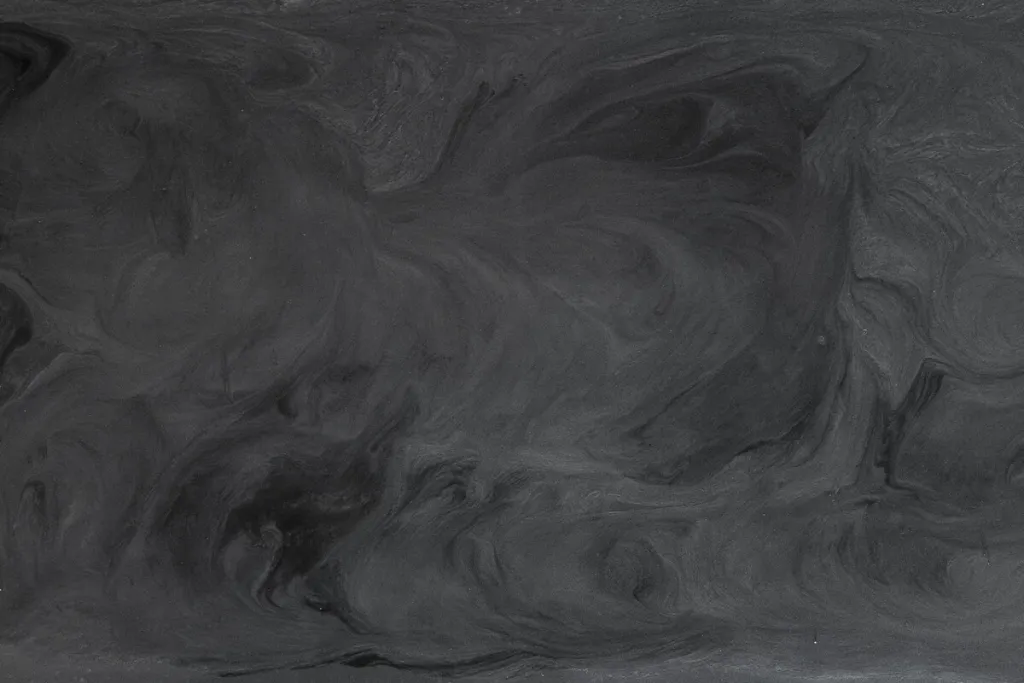

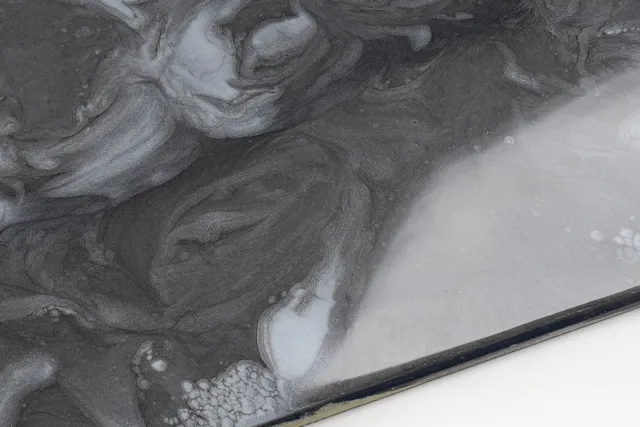

Epoxy Resin for Floor Coatings - SATIN GREY & DEEP BLACK

Shop epoxy resin design floors, garages (garage sealers), basement floors, stone carpets, industrial and warehouse floors, etc.

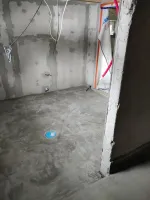

- Can be used on all surfaces such as concrete, screed, wood and more

- Material: Epoxy Resin to pour

- Properties: odourless, abrasion-resistant, waterproof, UV-stabilised, high coverage

- Working time: primer 120min., main coat: 120min.

- Curing time: Primer 8-12hrs., main coat 16-24hrs.

- Scope of delivery: Primer + epoxy resin and hardener + colouring agents

- Application instructions can be found on this product page

1. Select colour : SATIN GREY & DEEP BLACK

2. Quantity of epoxy resin (Resin A + Hardener B)

Universal Sealer (Optional) :

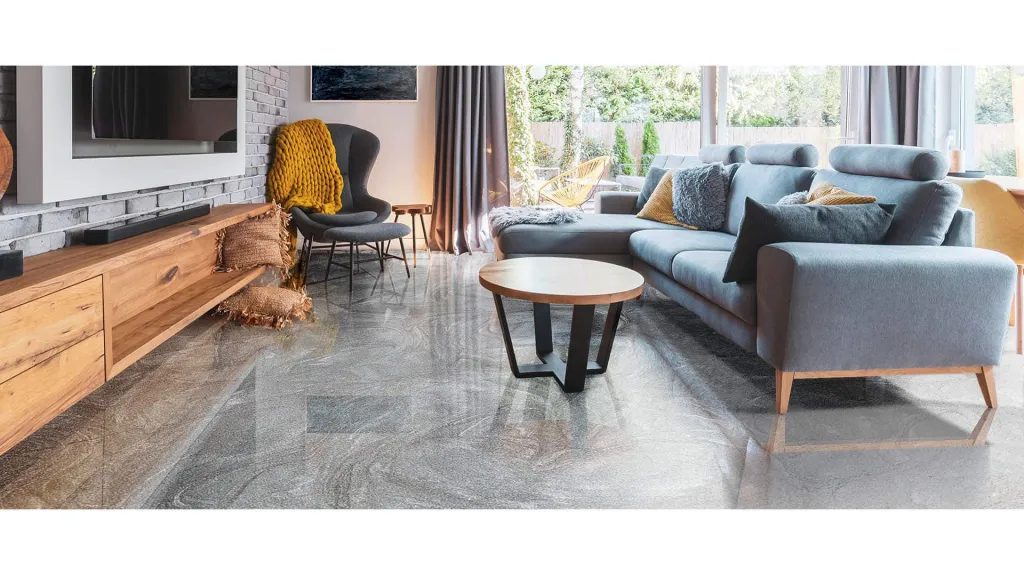

Design flooring & epoxy resin floor sealants

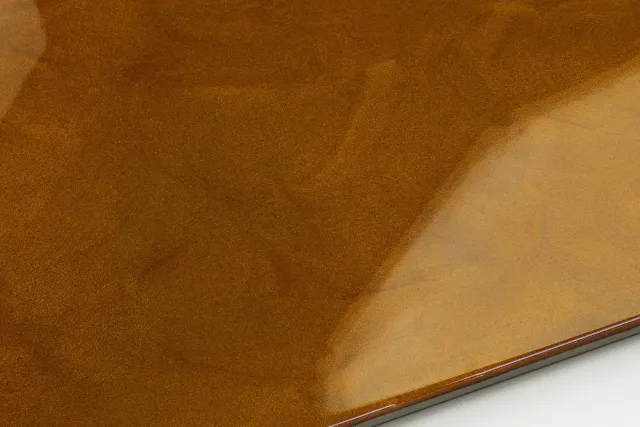

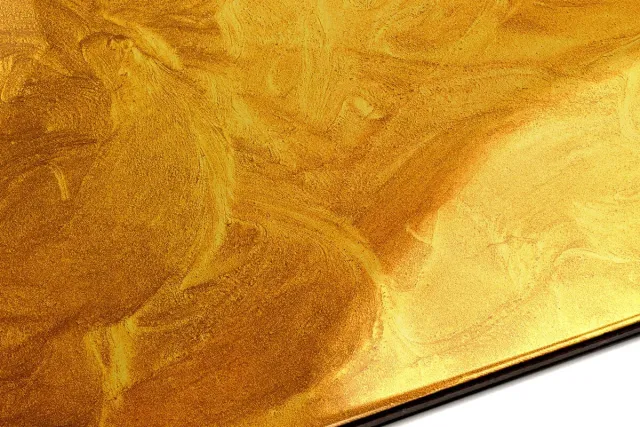

With our two-component epoxy resin sets for floors, you are always on the safe side. No matter whether it's a design floor or a classic floor seal for cellars and garages. Conveniently select your desired colour, determine the squareness and off you go! Get unique stone, marble and granite looks and save money compared to real marble stone. What are you waiting for? - Give your home a unique look!

100% safe epoxy resins –

Play it safe with your health! EPODEX epoxy resins are non-toxic (according to GHS06) and non-hazardous to health (according to GHS08) according to the hazardous substance legislation of the EU and Switzerland. Our high-quality epoxy resins are 100% solvent-free and, according to the formulation, do not contain any free bisphenol A (i.e., BPA-free), which is harmful to health. This guarantees pleasant processing.

No. 1 coating resin with bubble-free curing

Our epoxy resins self-vent at room temperature. This means that any air bubbles created by mixing and pouring will disappear on their own before the epoxy cures. Thanks to our unique formula, you do not need a spiked deaeration roller or other equipment to remove the bubbles.

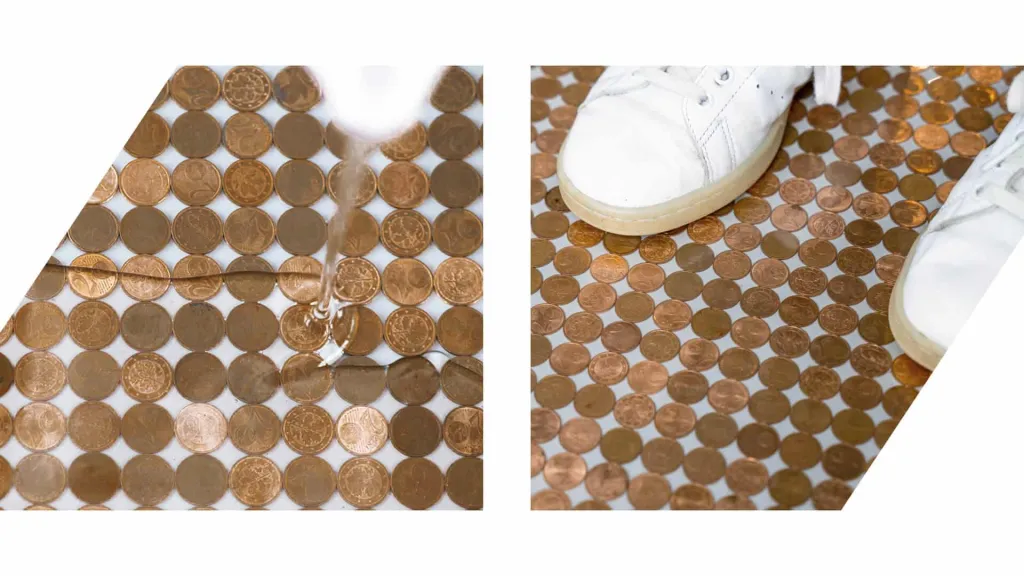

Cast 3D Pennyfloor yourself!

You want to cast a 3D floor? No problem, our clear epoxy resin set allows you to create a crystal-clear coating! Pour in coins and other things and wow your friends and guests with an absolute eye-catcher!

Instructions for Use metallic SATIN GREY & DEEP BLACK

Primer

- We recommend a working temperature of approx. 20°C.

- The floor should be dust-free, clean, and even. Level out holes, unevenness, and slopes in advance with levelling compound.

- Always start with our EPOXY PRIMER (primer).

- Pour the material into a paint tray after mixing.

- Roll the material onto the desired surface with a paint roller.

- Allow the primer to dry (approx. 8-12 hours).

Main Coat

- Use our ECO epoxy resin system (resin + hardener) for the main coating.

- Divide the amount of resin (A) and hardener (B) proportionally between the two metallic colours supplied, i.e., 95% of the resin to the base colour SATIN GREY, 5% of the resin to the highlight colour DEEP BLACK.

- First, apply the base colour SATIN GREY.

- Mix the resin (A) with the hardener (B) in a ratio of 2:1 by weight (e.g., 1kg A + 0,5kg B).

- Ideally, transfer the material to a clean mixing bucket and stir again. This will ensure that the resin (A) and hardener (B) are completely mixed together.

- Add the supplied SATIN GREY metallic pigment to the resin/hardener mixture. We recommend a colour proportion of approx. 1.5%, e.g., 15g pigment to 1kg resin + hardener.

- Pour the material onto the floor immediately after mixing, as the product can boil up in the mixing bucket.

- Apply the material with a squeegee and foam roller flooding the entire floor. We recommend a layer thickness of 1.5mm.

- Now apply the highlight colour DEEP BLACK in the same way and work the colour wet in wet into the base colour as a highlight.

- The main coating can be walked on after approx. 20 hours and is completely chemically cured after approx. 7 days.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely (at least 7 days). For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 20°C) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption volumes

Determine the required amount of resin needed with the help of our epoxy resin “Epoxy calculator” on this product page.

Recommended thicknesses when coating floors and other surfaces

- Overall coating (primer + main coating): approx. 1.9kg/sqm for layer thicknesses of 1.7mm

- Primer: approx. 0.2kg/sqm for layer thickness of 0.2-0.3mm

- Main layer: approx. 1.65kg/sqm for layer thicknesses of 1.5mm

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colours may not be uniformly displayed.

reviews

Warning Danger

Causes severe skin burns and eye damage. Causes skin irritation. May cause an allergic skin reaction. Causes serious eye irritation. Harmful if inhaled. Toxic to aquatic life with long lasting effects. Harmful to aquatic life with long lasting effects. Contains epoxy constituents. May produce an allergic reaction. Flammable liquid and vapour. May be fatal if swallowed and enters airways. May cause damage to organs through prolonged or repeated exposure. May cause respiratory irritation. May cause drowsiness or dizziness. The information on the product label must always be followed.