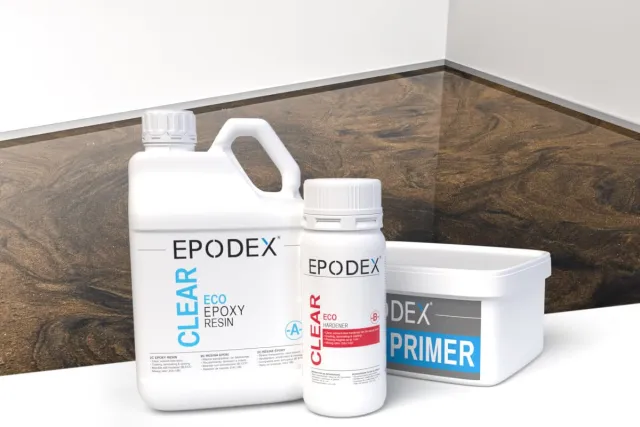

Epoxy Resins for River Tables & Castings up to 10cm (ECO MAX/ PRO MAX)

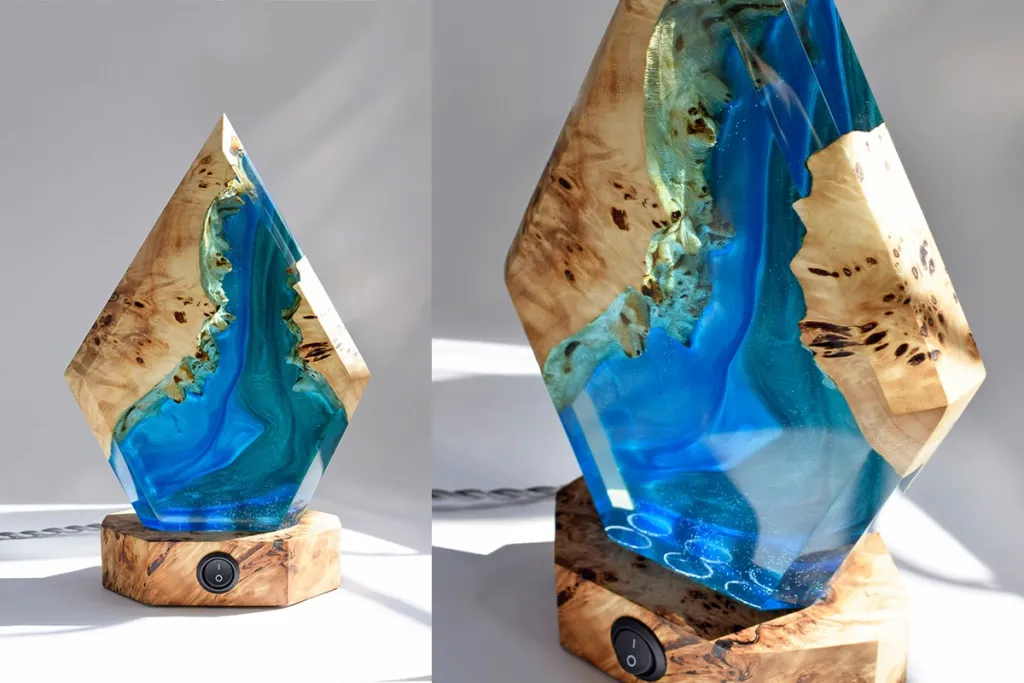

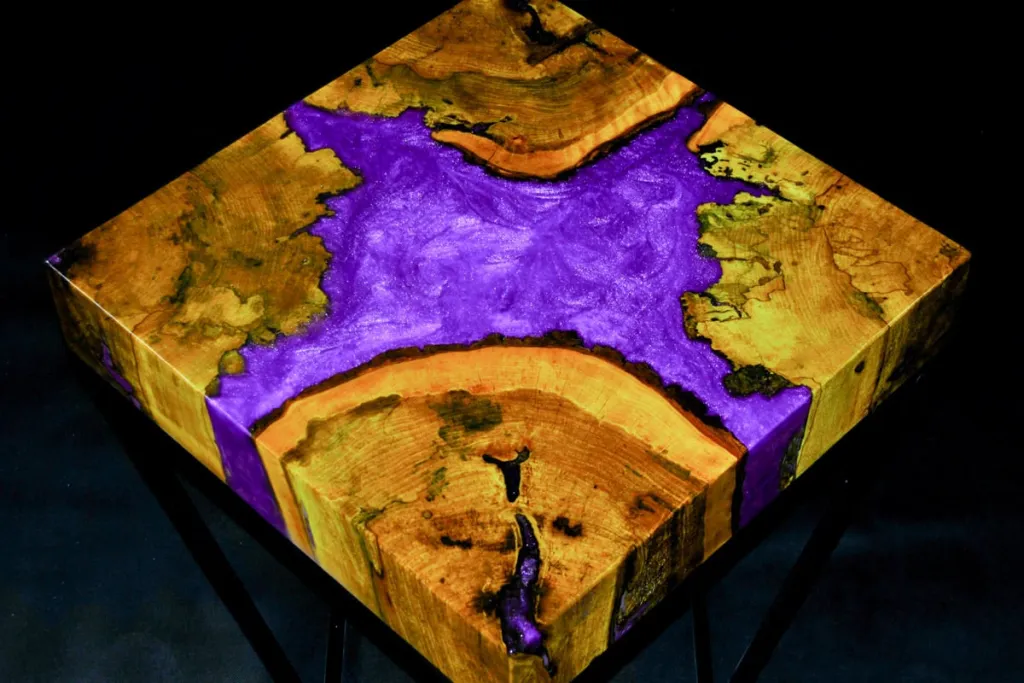

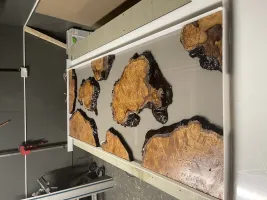

River tables, lamps, projects with very high mouldings and castings, etc.

- Can be used on all surfaces such as wood, concrete, glass and more

- Max. thickness per layer: 10cm (heights up to 50cm possible for small castings)

- Working time: approx. 8h, Curing time: 72-96h

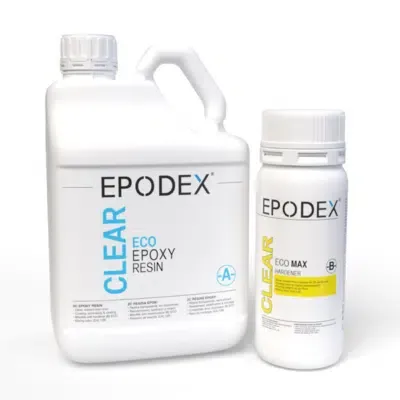

- Scope of delivery: Resin A and hardener B (Mixing ratio 2:1)

- Conveniently select a colour to colour the clear epoxy resin

1. Select colour

2. Select epoxy resin system

ECO MAX (Height up to 10cm)

PRO MAX (Height up to 10cm)

3. Quantity of epoxy resin (Resin A + Hardener B)

PU Sealer for Epoxy resin (Optional) :

Exceptional quality - directly from the manufacturer!

With our two premium epoxy resins, ECO MAX and PRO MAX you can reach high and realise pours up to 10cm height in one pouring process. Pour large river tables, lamps, and other tall projects in no time. While the cheaper ECO MAX system is mainly suitable for coloured projects, with the PRO MAX you can master both crystal clear and coloured pours with success!

100% safe epoxy resins

Play it safe with your health! EPODEX epoxy resins are non-toxic (according to GHS06) and not hazardous to health (according to GHS08) according to the hazardous substance legislation of the EU and Switzerland. Our high-quality epoxy resins are 100% solvent-free and, according to the formulation, do not contain any free bisphenol A (i.e., BPA-free), which is harmful to health. This guarantees pleasant processing.

No. 1 casting resin with bubble-free curing

No more annoying air bubbles and unevenness! Our epoxy resins self-vent at room temperature. This means that all air bubbles caused by mixing and pouring disappear on their own before the epoxy cures. You do not need a heat gun to remove the bubbles. This means that there is no risk of soot stains on your epoxy resin.

Crystal clear & UV stabilised

Don't compromise and choose the clearest epoxy resin on the market. Get a *money-back guarantee now: If you find a resin that is clearer than our PRO MAX epoxy, we'll give you your money back! (*valid up to 30 days after order). Our PRO MAX epoxy resin also offers the maximum possible UV protection. In this way, we effectively counteract the UV-induced yellowing of the casting resin.

Epoxy Resins for River Tables & Castings up to 10cm (ECO MAX/ PRO MAX)

EPODEX epoxy resin is ideal for a variety of applications. From construction, through electrical engineering and furniture coating. Coat your floors, tabletops and other items. Seal pictures or make your own jewellery. No matter your project, we can help you achieve it. Our epoxy resin systems are miscible with all our colours.

Application examples can be foand in the gallery.

Instructions for use

- Always start with an epoxy resin primer to avoid high material loss and blistering (layer thickness: 0,2-0,5mm). To do so, simply use a portion of the same clear epoxy resin. Mix the resin A-component with the hardener B-component in a ratio of 2:1 (e.g. 2kg resin: 1kg hardener).

- Stir through the edge and bottom of the mixing cup as the material will settle there. Ideally, pour into a clean mixing cup and mix again until the mixture is streak-free. This ensures that the resin A-component and hardener B-component are completely mixed together.

- Pour the resin-hardener mixture onto the surface to be coated immediately after mixing, as the product may boil in the mixing cup depending on the system and the amount of substance.

- Paint the epoxy primer with a paint roller or brush on the desired surface. We recommend rollers made of polyamide. Let the primer cure.

- Continue with the main coating in the same way. Processing times, pouring heights and curing times vary depending on the epoxy resin system selected and the application. You can find more detailed information in our information table under the “Select Epoxy System” button on this product page.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely (at least 7 days). For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 20°C) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption volumes

Determine the required amount with the help of our epoxy resin "Epoxy calculator" on this page.

Recommended thicknesses when coating floors and other surfaces

- Overall coating (primer + main coating): approx. 1,65-2,20kg/sqm for layer thicknesses of 1,5-2mm

- Primer: approx. 0,22-0,55kg/sqm for layer thickness of 0,2-0,5mm

- Main layer: approx. 1,10-1,65kg/sqm for layer thicknesses of 1-1,5mm

Recommended amount of colouring agent per kg of resin+hardener:

- Powder pigments (Metallic, Neon and Glow in the dark): 1,5% (15g),

- Transparent dyes (except white, black and grey): 60 drops (1,8g),

- Transparent white, black and grey dyes: 20 drops dye (0,6g),

- Semi-transparent dyes (except white): 40 drops (1,2g) of the desired colour and 20 drops (0,6g) of white dye,

- Semi-transparent white: 60 drops of white dye (1,8g),

- RAL solid colour: 1% (10g),

- Glitter pigments: 1% (10g)

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colours may not be uniformly displayed.

Reviews

Warning Danger

Warning Danger Causes skin irritation. May cause an allergic skin reaction. Causes serious eye damage. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. Harmful if swallowed or in contact with skin. Harmful if inhaled. May cause respiratory irritation. Contains isocyanates. The information on the product label must always be followed.