Make Your Own Epoxy Resin Table

Order high-quality epoxy resin now and easily cast your epoxy resin tables, river-tables and much more. Choose your epoxy resin product depending on the desired layer thickness (casting height):

Our Promises

Your needs and wishes always come first for us

Bubble-Free Curing

Our resins are specially formulated so that any air bubbles that may occur during mixing and pouring go away on their own.

Made in Germany

We are complying to the highest quality standards and always reaching out for more by constantly improving our existing products.

100% Safe Resin

Our resins are according to the EU hazardous substances legislation non-toxic (according to GHS06) and not hazardous to health (according to GHS08).

Solvent and BPA-Free

Our resins are completely solvent-free and, according to the formulation, do not contain free bisphenol A, which is harmful to health.

Table Coating at The Best Price

Whether you’re redesigning an epoxy table or customising and refurbishing an older table, we have everything you need. Our simple step-by-step instructions will quickly guide you through the process. Use our synthetic resin on wood, plastic, rigid foam, natural stone, GRP or concrete.

Unique design tables, eye-catching river tables or epoxy resin to seal table tops for the hospitality industry – EPODEX’s resin is ideal for your project.

How Much Epoxy Resin do I need?

To make an epoxy resin table, first measure the surface of your table. Then decide which layer thickness you would like to apply. Our smallest quantity is enough to seal a 3m² table top.

Use our epoxy resin calculator to quickly find out how much resin and hardener you need. Then, select the right quantity and you will receive a complete kit including resin, hardener, and the desired colouring agents for your project. Standard delivery time takes approximatively 1-3 working days. After receiving your order, you are good to go - You can start your epoxy resin table project!

How Durable is an Epoxy Resin Table?

Would you like to design a unique table that’s durable and easy to maintain? A coating with epoxy resin is the right choice. The synthetic resin is easy-to-process, cures firmly and is highly durable and stable.

An epoxy resin is highly resistant to liquids, scratches, and stains. An epoxy resin table does not require any special care. It can be cleaned with common all-purpose cleaners and will remains as good as new for years to come.

In contrast to untreated wooden tables, epoxy tables do not require regular maintenance. Epoxy resin table coatings are often used in restaurants and bars, where tables/countertops are subject to heavy wear and tear. EPODEX's epoxy resin is like a life-insurance for your table.

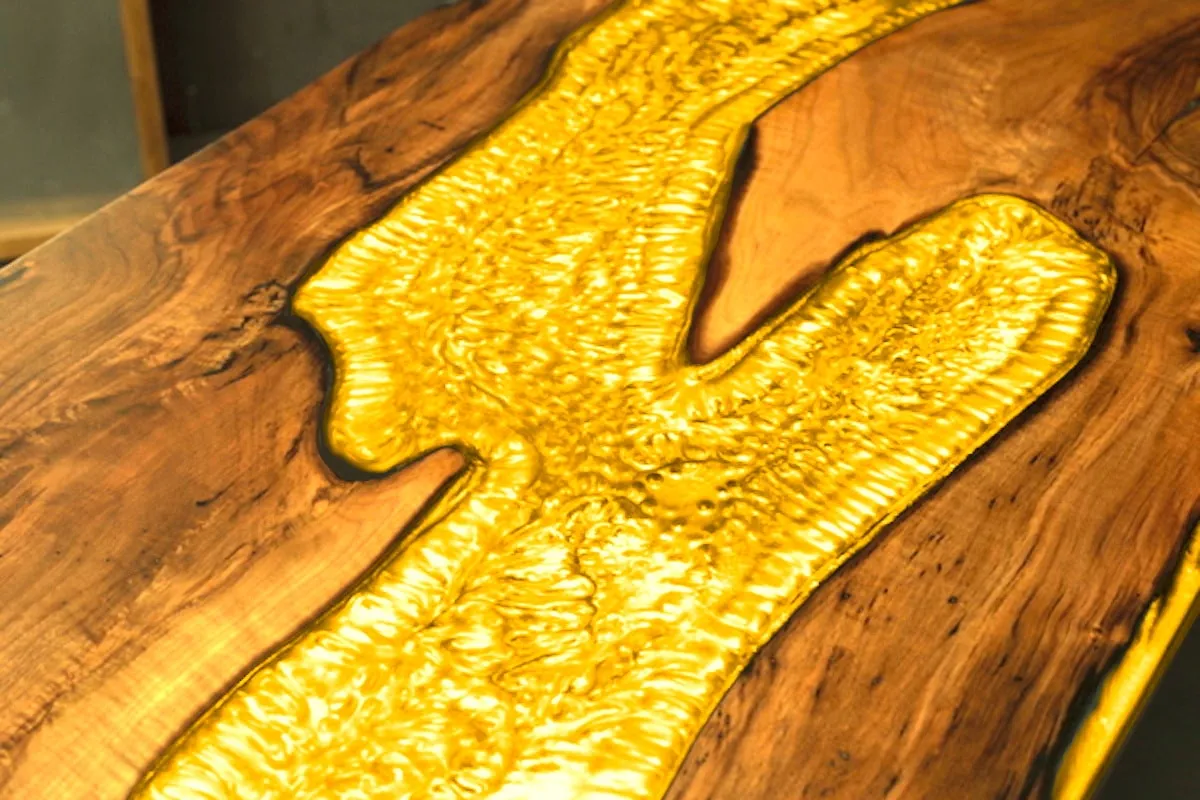

Epoxy Resin Table – Achieve Your Own DIY Design

Epoxy resin is a material with endless possibilities in terms of creativity. It can be moulded into almost any shape and dyed in countless colours. Special effects can also be achieved when mixing different colouring agents together.

You can include objects into the transparent epoxy and create a unique design. There are really no limits to your imagination and every piece is unique! We’ll provide you with a all-inclusive carefree package to make your table a real eye-catcher!

Start your epoxy resin table project with EPODEX now. Find out more epoxy resin ideas and let yourself inspire by our Pinterest and Instagram accounts!

How do I seal a Table with Epoxy Resin?

First, thoroughly clean the table to be coated and let it dry. Then, start with the primer. To do so, mix enough synthetic resin and hardener together to apply a thin layer of 0.2 to 0.5mm. Follow the mixing and curing instructions on each product page.

Continue with the main coating, once the primer is cured. The easiest way to apply the resin is with a squeegee or foam roller. Pay attention to the maximum pouring height of each product and proceed in many layers according to the instructions to achieve a greater thickness.

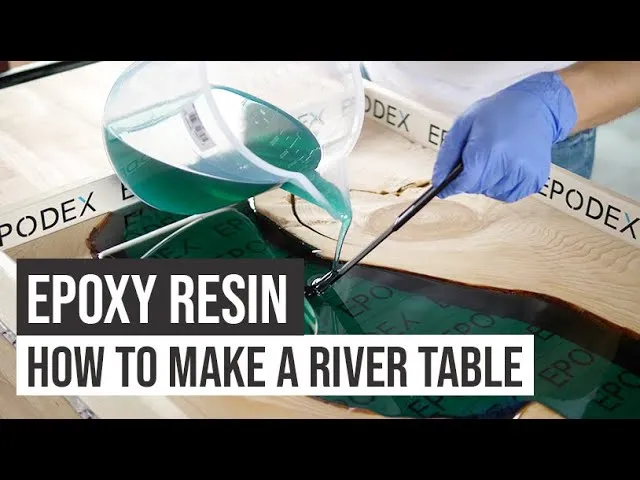

How do I make a River Table?

You would like to make a river table or an epoxy resin table with embedded objects? To do so, we recommend our PRO+ or PRO MAX epoxy resin system, which allows you to pour thicker layers in just a few steps. This premium resin is particularly user-friendly and very easy-to-use. You can find detailed instructions for use as well as applications example on each product page. You'll also find a tutorial on how to make your own river table on our YouTube channel and our EPODEX's Blog.

STEVE SMITH

Any questions? I am glad to help!

We are here to help you with your epoxy resin table

Think about how you want your epoxy table to look and we will deliver everything you need to achieve your DIY project. Do you have questions or feedbacks? Get in touch with us. You can easily reach us by phone, email and WhatsApp. Our expert team will gladly guide you through your next project!

What is an Epoxy Resin Table?

An epoxy table is either a table that has been sealed with epoxy resin or a table that is mostly made of epoxy resin. This type of table is also known as a "river table".

Can tables be coated with Epoxy Resin?

Especially in the commercial and hospitality industries, it is worth sealing tables with resin. This makes them considerably more resilient and also gives them a perfect glossy finish. It is also possible to change the colour of the table with epoxy resin.

Where can you buy Epoxy Resin Tables?

These are mostly custom-made, one-of-a-kind items that are not available in regular shops. You can shop epoxy resinto make your own table on EPODEX.

How do you make an Epoxy Resin Table?

Here you have to distinguish whether you want to coat an existing table with self-levelling resin or whether you want to make a new table from scratch. To seal and make a new table, you need a mould, epoxy resin and, if desired, wooden planks.

What do you need to make a River Table?

To make a river table, you need a mould, epoxy resin, colouring agents, and wooden planks. You can find detailed instructions written on our blog or as a video on the EPODEX Media Library.

How Expensive is an Epoxy Resin Table?

The price depends largely on the size and the materials used. Therefore, it is not possible to give a general answer to this question.