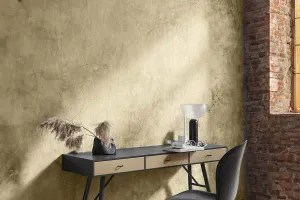

Microcement set for walls

Microcement of premium quality for wall surfaces of all kinds indoors and outdoors. Living areas, commercial spaces, facades, and more.

- Design filler applicable to all surfaces such as concrete, metal, plastic, wood, etc.

- Material: Microcement fine/medium (Component A) and acrylic resin (Component B)

- Properties: High load-bearing capacity, weatherproof, UV-stable, odourless

- Areas of application: Interior & exterior as well as damp rooms with PU sealing

- We recommend 2 layers: Layer 1 (medium): 1.2kg/m², Layer 2 (fine or medium): 1-1.2kg/m²

- Waiting time between layers: min. 8h max. 24h

- Scope of delivery for 7m² (Fine-grained): 7kg medium + 5kg fine + 4kg acrylic resin + colourants

- Scope of delivery for 7m² (Medium-grained): 14kg medium + 4kg acrylic resin + colourants

Please make your selection in the following order.

1. Select colour

2. Select texture

3. Select quantity (m²) for 2 coats

Please make your selection in the following order.

Application | |

| Product Description | Microcement, nano concrete, design levelling compound |

| Area of Application | Area of Application Close to all walls and floors, furniture etc., walls, facades, stairs, industrial halls, cellars etc. |

| Field of Application | Indoor & Outdoor use and damp rooms |

| Method of application | Trowel |

| Self-levelling | minimal; must be spread and smoothed out with a trowel |

| Consumption Quantity Floor | Layer 1 (Large): 1.6kg/m², Layer 2 (Large or Medium): 1.2kg/m² |

| Consumption Quantity Wall | Layer 1 (Medium): 1.2kg/m², Layer 2 (Medium or Fine): 1kg/m² |

| Odour development during application | Low (according to amine) |

| Spray and Drip Behaviour | Depending on processing consistency, dripping possible on wall surfaces |

| Application Temperature | Substrate and ambient temperature must be min. 10°C and max. 30°C |

| Optimum Processing Temperature | 20°C |

| Mixing ratio by weight Powder (A): Liquid (B) | Fine: 100:35, Medium: 100:20, Large: 100:25 |

| Recommended layer thickness | fine 1mm; medium and large 1.5mm |

| Recommended number of layers | min. 2 layers |

| Waiting time between layers | max. 24 hours |

| Waiting time before painting over with another product | after 48 hours |

| Primer on absorbent substrates | Deep Primer 1K recommended |

| Primer on non-absorbent substrates | Primer 2K recommended |

| Max. humidity level during application | 60% |

Technical Properties | |

| Material Base | Cement |

| Component A | Powder for Microcement and Quartz |

| Component B | Acrylic Resin in Water Dispersion |

| Gloss Level | Satin matt. High gloss and dull matt possible with PU sealer |

| Consistency | High viscosity, viscosity can be adjusted depending on the amount of LIQUID (B) added. |

| Coverage | Highly Opaque |

| Surface Finish | Highly durable, abrasion-resistant, hard-wearing, scrub-resistant |

| Scratch Resistance/Abrasion Resistance | Reinforced by the application of PU and recommended for heavily used surfaces and wet areas |

| Compressive Strength after 7 days | ≥ 12.0 MPa (EN 13892-2) |

| Compressive Strength after 28 days | ≥ 20 MPa (EN 13892-2) |

| Flexural Strength after 7 days | 4.0 MPa (EN 13892-2) |

| Flexural Strength after 28 days | 7.0 MPa (EN 13892-2) |

| Fire resistance class | Efl EN 13501-1 |

| Shore Hardness | ≥80 |

| Elasticity1 | Not elastic; glass fibre mesh must be incorporated on substrate susceptible to vibrate |

| Open to diffusion, breathable | Yes (unless 2 or more layers of PU sealant are applied) |

| Application in Wet Areas | Not recommended without Pu sealant in wet areas |

| Colour Fastness | High |

| Colour Intensity | High |

| Colour Appearance | For walls: Fine/medium texture - For floors: Medium/Large texture |

| UV-resistant | UV-Stable |

| Solvent-Free | Yes |

| Plasticiser-Free | Yes |

| VOC-Free | Yes |

| Susceptible to abrasion marks and gloss spots (so-called writing effect) | Low (Touch-Protect-System) |

| Environmentally Friendly | Yes |

| Pigment Content | 2-10% depending on desired colour intensity, recommended 2% |

| Density (g/cm³) | 800 - 1300 kg/m³ |

| Maximum Grain Size | Large (450µm), Medium (330µm), Fine (80µm) |

| Dilutable | Fine: max. 100:40, medium: max. 100:23, large: max. 100:28 |

| Tool Cleaning | Tool Cleaning Immediately after use with acetone/thinner |

| Chemical Resistance | Acids, alkalis and chlorine should be avoided |

| Surface Cleaning | Light surfactants (do not use acidic or chlorinated cleaners or alkaline solutions) |

| Storage Temperature | Airtight, cool, dry, and frost-free |

| Max. Storage Temperature | 25°C |

| Min. Storage Temperature | 10°C |

| Minimum Shelf Life | Unopened 12 months, Open 6 months |

- If the substrate presents expansion joints, these must be taken into account when applying microcement. The expansion joint must either be reinforced with fibre glass mesh or a joint must be included into the microcement. Rooms larger than 50m² should always include expansion joints. Ignoring existing expansion joints or not including them when needed can lead to the microcement cracking.

1. Select colour

2. Select texture

3. Select quantity (m²) for 2 coats

PU Sealer for Microcement (Optional) :

Mikrozement Design

EPODEX microcement is a special levelling compound for designing floors, walls, stairs, tables, and other surfaces in a modern seamless design. Create a unique, contemporary ambience in no time at all. We will show you all microcement techniques, from exposed concrete with natural cavities to multi-coloured designs with 3D applications.

Universally Applicable

Our microcement is suitable for indoor and outdoor use and can be applied to almost all surfaces such as parquet, tiles, natural stone, plasterboard, metal, ceramic, marble, OSB and more. The material is highly resilient and UV-resistant. At the same time, it remains flexible and breathable.

Completely Waterproof

EPODEX microcement in combination with our polyurethane resin (PU) sealant is waterproof and weather resistant. It is therefore ideal for showers and outdoor areas. The sealing layer is finally rolled onto the hardened microcement. Depending on your requirements, you can choose between our matt and gloss PU sealant.

Instructions for Use

Primer

- The substrate must be stable, dry, and free of dirt, separating agents, and coarse unevenness.

- Sand off any unevenness.

- For tiled surfaces, we recommend priming the tiles with our 2K PRIMER for non-absorbent substrates and filling the joints with it.

- Allow the primer to dry.

Main Coating

- Mix microcement A components in medium grain size with the B component in the specified mixing ratio.

- Add WB pigment in the recommended quantity to colour the material.

- Spread the material with a trowel and then leave to dry

- Sand off any unevenness in the surface greater than 3 mm and vacuum up any sanding dust.

- Apply a second coat in the same way. Depending on the desired finish, the microcement can be applied in medium or fine grit.

Sealant

Note: For damp rooms, surfaces in direct contact with water and heavily used surfaces (high mechanical stress, cleaning with aggressive cleaning agents, etc.), we recommend sealing the surface with EPODEX polyurethane resin (PU resin) in matt or glossy.

- Mix PU resin and hardener in the specified mixing ratio and pour into a paint tray.

- Apply the material thinly with a foam roller in a crosswise motion and allow to harden. We recommend two coats.

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colours may not be uniformly displayed.

Reviews

Warning Danger

Warning Danger Causes serious eye damage. Causes skin irritation. May cause respiratory irritation. May cause an allergic skin reaction. Harmful if inhaled. Contains isocyanates. The information on the product label must always be followed.