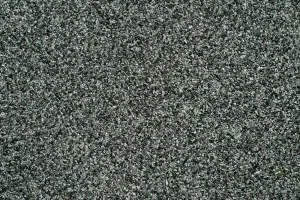

Stone Carpet Set - Verde

Stone Carpet for Floors, Pools, Stairs, and Other Surfaces

- Suitable for all load-bearing substrates, including concrete, screed, wood, and more.

- Properties: Highly Resistant, Weatherproof, UV-resistant

- Area of Application: Indoors & outdoors

- Consumption Volume: 13.3kg/m²

- Processing Time: 45min at 20°C

- Drying Time: 24h at 25°C

- Supplied per m²: 12.5kg natural stone/quartz stone + 0.8kg PU BINDER

- Optional Extra: PU PRIMER to prime and PU FILLER to seal the gaps between the stone aggregates

- For coating stair risers, we recommend using our "PU VERTICAL BINDER". You can find it under the Accessories button on this product page.

Please make your selection in the following order.

1. Select colour

2. Select quantity

Please make your selection in the following order.

| PU PRIMER | Stone Carpet ( Stone Aggregates+PU BINDER) | PU FILLER | |

Applications | |||

| Product Description | Stone Carpet Primer | Stone Carpet Main Coating | Stone Carpet Sealant |

| Area of Application | Can be applied to absorbent and non-absorbent, as well as dry and damp substrates. | Floors, walls, pools, stairs, and other surfaces. | Wet areas, showers and pools, as well as all surfaces where easier cleaning is desired. |

| Field of Application | Indoors & Outdoors | Indoors & Outdoors | Indoors & Outdoors |

| Method of application | To roll on the surface | Trowel: We recommend spraying the trowel regularly with a mixture of dish soap and water to keep it clean.³ | Spatula and Rubber Squeegee⁴ |

| Consumption | approx. 150-250g/m² depending on the porosity of the substrate | 12.5kg stone chips and 0.8kg PU BINDER per m² with an 8mm layer thickness | 0.8kg per m² |

| Range/yield* | approx. 4-6m²/kg | approx. 0.07m²/kg | approx. 1.25m²/kg |

| Odour development during processing | Intense | Intense | Intense |

| Spraying and dripping behaviour | Very low (no splashing) | Very low (no splashing) | Very low (no splashing) |

| Processing temperature | min. +10°C and max. +25°C | min. +5°C and max. +40°C do not apply in rain or snow | min. +5°C and max. +40°C do not apply in rain or snow |

| Optimum processing temperature | 20°C | 20°C | 20°C |

| Max. Air humidity during processing | - | 85% | 85% |

| Mixing ratio by weight Stone Chips : Binder | - | 100:6 | - |

| Layer thickness | - | 8mm | Product evens out the surface by filling pores; no additional layer build-up |

| Pretreatment | If possible, clean the surface with a high-pressure cleaner. Remove oil, grease and wax contamination. Cement slurries, loose particles, mould release agents and cured membranes must also be removed. | EPODEX PU PRIMER and, if desired, attach edge profiles to the edges for a clean finish. For this purpose, use our assembly adhesive, for example. | apply to cured EPODEX stone carpet |

| Recommended number of layers | 1 | 1 | 1 |

| Waiting time until further processing | 1 hour at 25°C or until the PU primer has hardened | min. 24 hours at 25°C | - |

| Pot life at 20°C | approx. 25 min. | approx. 45 min. | approx. 30 min. |

Technical properties | |||

| Material base | Polyurethane fully aliphatic | Polyurethane fully aliphatic | Polyurethane fully aliphatic |

| Degree of gloss | glossy | glossy | glossy |

| Consistency | low viscosity (thin liquid) | solid | pasty |

| Dilutable | no | no | no |

| Touch dry/walkable after | after 1 hour at 25°C | after 24 hours | after 24 hours |

| Properties | permanently elastic, fast-curing, resistant | heavy-duty, weatherproof, resistant | weather-resistant, UV-resistant, waterproof even with permanent water contact |

| Surface finish | heavy-duty, abrasion-resistant, hard-wearing, scrub-resistant | heavy-duty, abrasion-resistant, hard-wearing, scrub-resistant | heavy-duty, abrasion-resistant, hard-wearing, scrub-resistant |

| Scratch resistance/abrasion resistance | Yes | Yes | Yes |

| Chemical resistant | Yes | Yes | Yes |

| Diffusion-open, breathable | No | Yes | No |

| Colour fastness | Yes | Yes, EPODEX stone chips consist of natural stone/quartz stone and retain their colour outdoors. | Yes |

| Colour image (appearance) | colourless | depending on stone chips | transparent |

| UV-resistant | Yes | Yes | Yes |

| VOC-free | Yes | Yes | Yes |

| Environmentally friendly | Yes | Yes | Yes |

| Viscosity at 20°C (mPas) | 75-115 | 900 - 1200 | 2000 - 3000 |

| Density (g/cm³) | 0.95 - 1.05 | 0.95 - 1.05 | 1 |

| Flash point | 28°C | 30°C | 30°C |

| Hardness (D Shore) | - | 60 | 60 |

| Thermal resistance (100 days at 80°C) | - | passed | passed |

| Max. Heat resistance up to | - | +80°C and max. shock temperature +200°C | +80°C and max. shock temperature +200°C |

| Min. Heat resistance up to | - | -40°C | -40°C |

| Grain size | - | 2-4mm | - |

| Tool cleaning | Immediately after use with water and thinner | Immediately after use with water and thinner | Immediately after use with water and thinner |

| Storage | Store only in the original container, well closed, cool, frost-free and in the dark. Protect from sun | Store only in the original container, well closed, cool, frost-free and in the dark. Protect from sun | Store only in the original container, well closed, cool, frost-free and in the dark. Protect from sun |

| Minimum shelf life after receipt² | 12 months | 12 months | 12 months |

| Minimum shelf life after opening² | Use up quickly after opening | Use up quickly after opening | Use up quickly after opening |

| max. storage temperature | 25°C | 25°C | 25°C |

| Surface cleaning | - | mild surfactants (do not use acidic, chlorine-containing cleaners or alkalis) | mild surfactants (do not use acidic, chlorine-containing cleaners or alkalis) |

| Safety precautions | Nitrile gloves (class 3 for short-term use and class 5 for prolonged or repeated contact)¹; In addition, we recommend wearing a class M3 or higher respiratory mask during mixing and processing of the material. | Nitrile gloves (class 3 for short-term use and class 5 for prolonged or repeated contact)¹; In addition, we recommend wearing a class M3 or higher respiratory mask during mixing and processing of the material. | Nitrile gloves (class 3 for short-term use and class 5 for prolonged or repeated contact)¹; In addition, we recommend wearing a class M3 or higher respiratory mask during mixing and processing of the material. |

| 1: From 24 August 2023, appropriate training must be provided before industrial or commercial use. | |||

| 2: The shelf life can be significantly reduced if the storage conditions are not properly observed. | |||

| 3: We recommend applying PU BINDER to vertical surfaces to improve the adhesion of the stone carpet. | |||

| 4: Use your rubber squeegee at a shallow angle and be careful not to apply an additional layer over the granules. If the pore-filling step is not carried out carefully, wavy unevenness could form. | |||

1. Select colour : Verde

2. Select quantity

PU PRIMER (Optional) :

PU-Filler (Optional) :

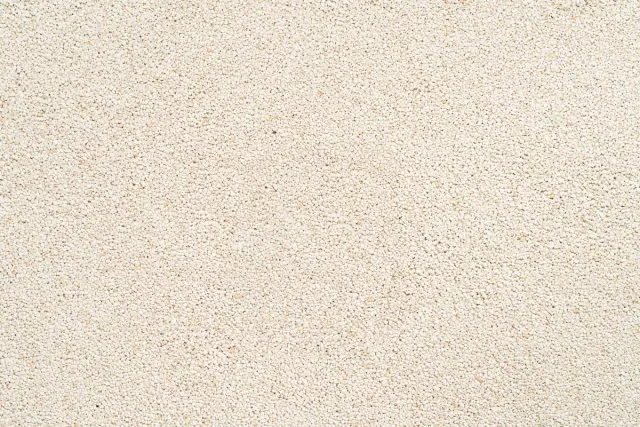

Seamless Design with EPODEX’s Stone Carpet

Say goodbye to boring flooring! With the EPODEX Stone Carpet, you can easily achieve a seamless, modern design both indoors and outdoors. Our team of expert designers has carefully selected a range of natural stones to reflect the latest trends and blend perfectly with any interior style—whether you prefer a minimalist Japandi aesthetic or a cosy boho-chic look. The EPODEX Stone Carpet will take your interior to the next level!

Stone Carpet – Durable & Low Maintenance

Tired of cleaning a floor that somehow always looks dirty? EPODEX’s Stone Carpet comes to the rescue! Our fine natural stones are comfortable to walk on, and our strong PU BINDER ensures long-lasting durability. Our stone carpet allows water to quickly and efficiently drain through, preventing puddles from forming and making it safer, for example, on your terrace or driveway. The PU FILLER makes the surface even easier to clean as it’s completely waterproofing the stone carpet.

Functional Aesthetics

With EPODEX Stone Carpet, you can bring your personality into the mix without compromise! Combine colours, patterns, and techniques to personalise your living room, bathroom, terrace, balcony, or driveway. The stone carpet effectively absorbs sound, making spaces quieter. Made up of 95% natural and sustainable raw materials, it’s also an eco-friendly flooring option.

Instructions for Use

- Ensure the substrate is load-bearing, clean, and free from any substances that may prevent proper adhesion.

- Prime the substrate with our PU PRIMER.

- Let the PU PRIMER dry (approx. 25°C: 1h).

- If desired, install edge trims to define the area and create a clean edge. To fix the edge trim, you can use, for example, our assembly adhesive.

- Prepare a mixture of water and dish soap into a spray bottle.

- Mix the stone aggregates with the supplied PU BINDER. To do so, add 6% PU BINDER to the dry-stone aggregates, for example, mix 12.5kg stone aggregates with 0.75kg PU BINDER.

- Pour the mixture immediately after mixing onto the surface to be coated.

- Spread the mixture with a trowel. Use the spray bottle containing the mixture of water and dish soap to clean the trowel and smooth the mixture easily.

- Let the stone carpet cure (approx. 24h at 25°C).

- For easier cleaning, the stone carpet can optionally be sealed with our PU FILLER. In wet rooms, such as the shower, or for pools, the use of our EPODEX PU FILLER is essential to create a waterproof surface. Apply the material with a spatula and then remove any excess using a rubber squeegee.

Reviews

Warning

Causes skin irritation. May cause an allergic skin reaction. Causes serious eye irritation. The information on the product label must always be followed.