Bodenfarbe von EPODEX

Laying an Epoxy 3D Flooring

Basically, laying 3D floors works just like any other floor coating. The main difference is that you embed objects between the layers. Before you start, you should clean the floor and repair any cracks or holes with epoxy putty, for example. Always wear nail soles, a breathing mask, and gloves.

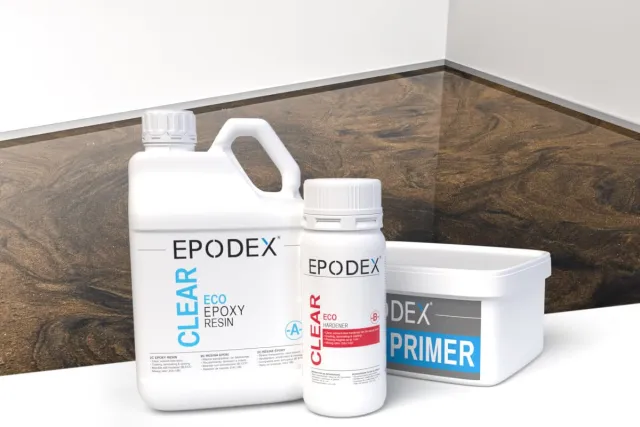

First, use an EP primer such as our EPODEX PRIMER. Allow the primer coat to dry completely before proceeding. The next step is to pour a casting resin system that will self-level and act as a support layer for the objects. Next, pour a layer of the self-levelling epoxy resin that will serve as a support for ou embeds. Make sure that you add the objects only after the resin has gelled a while. Otherwise, they may sink and thus ruin the desired 3D effect. When the resin has reached the right viscosity, you can embed the objects, seal them with a very thin resin layer and wait until it has cured completely. You can pour a final layer of casting resin. Allow the floor to cure according to instructions. Do not walk on or load the floor again until the curing time has elapsed.

STEVE SMITH

Any questions? I am glad to help!

3D Flooring in Your Bathroom

For a 3D floor coating in the bathroom or other rooms with high humidity, we recommend using our EPODEX PRIMER as a base. You can also use EPODEX ECO or PRO-only because once the resin has cured, it is resistant to moisture. Please note that the uncured resin is very sensitive to moisture and water, it is important to protect it until complete chemical curing. Use our quantity calculator on the product page to find out exactly how much resin you need for the area of the room. Design your 3D floor in the bathroom now and fulfil your dream of individual flooring.