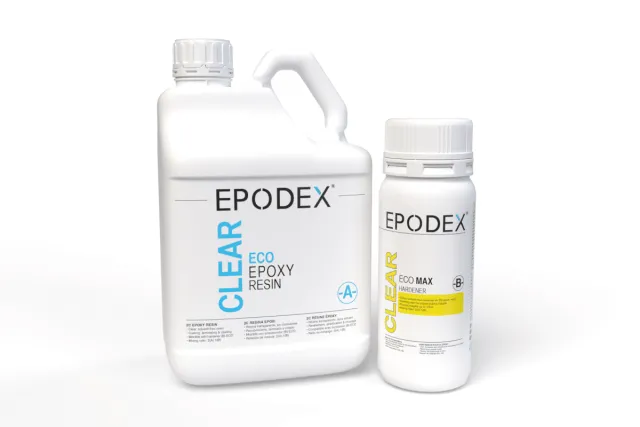

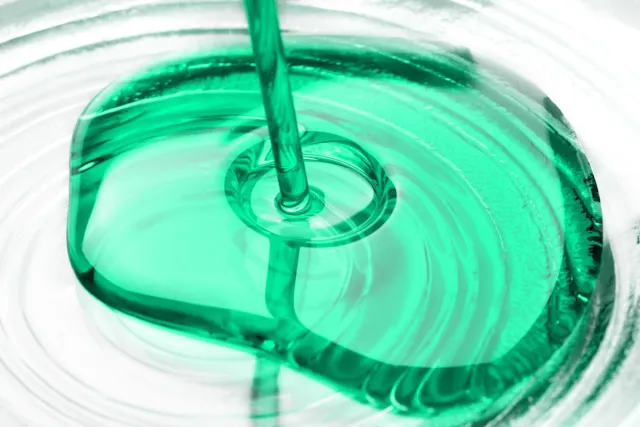

PRO MAX System (Epoxy Resin + Hardener)

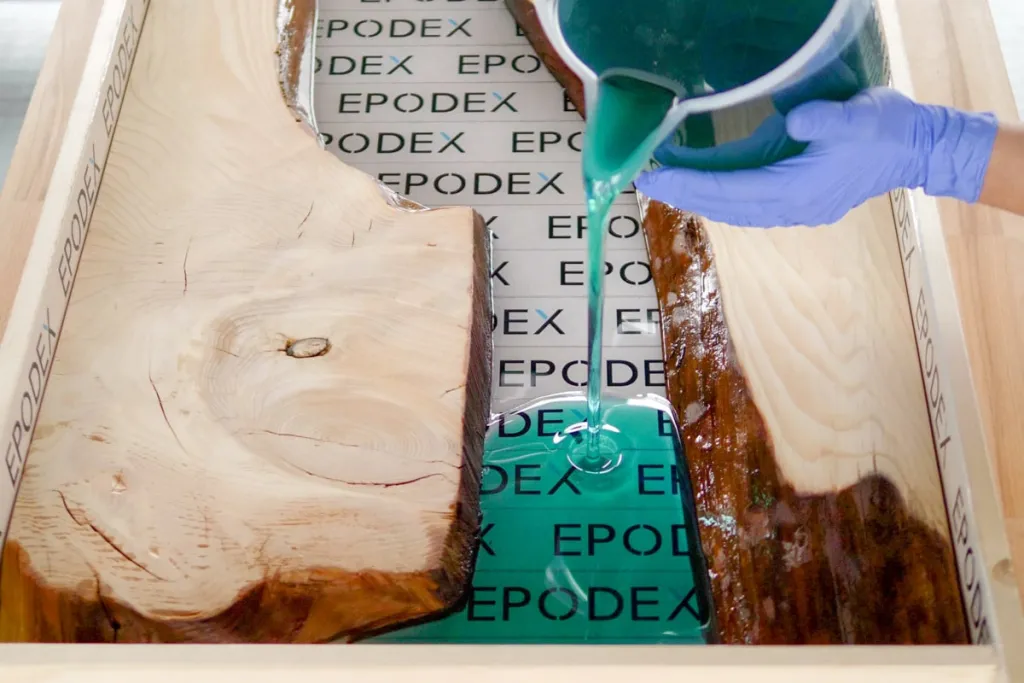

Max. Pouring height 10cm. Pouring of larger castings from one pour, as well as epoxy resin tables.

- Can be used on all surfaces such as wood, concrete, glass and more

- Max. thickness per layer: 10cm (heights up to 50cm possible for small castings)

- Working time: approx. 8h, Curing time: 72-96h

- Scope of delivery: Resin A and hardener B (Mixing ratio 2:1)

- Conveniently select a colour to colour the clear epoxy resin

Please make your selection in the following order.

1. Select colour

2. Quantity of epoxy resin (Resin A + Hardener B)

Please make your selection in the following order.

Legend:

| ✓ Ideally suited. | X Not suited. | ~ Not ideal, but can be used. |

| ECO | PRO | ECO+ PRO+ | ECO MAX PRO MAX | |

|---|---|---|---|---|

| Mixing Ratio by Weight Resin (A) : Hardener (B) | 100:50 | 100:50 | 100:50 | 100:50 |

Applications | ||||

| Coating | ✓ | ✓ | ~ | ~ |

| Laminating | ✓ | ✓ | ~ | ~ |

| Sealing | ✓ | ✓ | ~ | ~ |

| Pouring | ~ | ✓ | ✓ | ✓ |

| Repairing | ✓ | ✓ | ~ | ~ |

| Glueing | ✓ | ~ | ~ | ~ |

Application Areas | ||||

| Priming, Coating and Sealing of Floors (Industrial Floors, Garages, Interior Floors, Bath etc.) | ✓ | ✓ | X | X |

| Coating and Sealing of Tables, Countertops and Other Furniture/Objects | ✓ | ✓ | ~ | ~ |

| Sealing of Pictures | ✓ | ✓ | X | X |

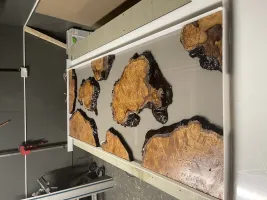

| Pouring of Tables (River-Tables) | ~ | ~ | ✓ | ✓ |

| Creation of Jewellery and Small Castings up to 2cm Height | ✓ | ✓ | ~ | ~ |

| Casting of large pieces in one pour | X | X | ✓ | ✓ |

| Isolation of Electrical Circuits and Terminal Points | ✓ | X | X | X |

| Use in Aircraft, Ship and Model Construction | ✓ | ✓ | ~ | ~ |

| Bonding and Sealing of Concrete, Wood, Plastic, Hard Foam, Natural Stone, Fibreglass and Other Materials | ✓ | ~ | ~ | ~ |

Processing Characteristics | ||||

| Wood Turning | ✓ | ✓ | ✓ | ✓ |

| Sandable | ✓ | ✓ | ✓ | ✓ |

| Polishable | ✓ | ✓ | ✓ | ✓ |

| Max. Pouring Height per Process1 | 1cm | 2cm | 5cm | 10cm |

| Waiting Time until Further Casting2 | 6h | 12h | 48-72h | 72-96h |

| Gelling Time and Pot Life | 25min (100g) | 65min (145g) | 6h (10kg) | 8h (10kg) |

| Min. Processing Temperature | 15°C | 15°C | 15°C | 15°C |

| Recommended processing temperature | 20°C | 20°C | 20°C | 20°C |

| Max. Relative Humidity during Processing | 70% | 70% | 70% | 70% |

| Max. Material Shrinkage | 1% | 1% | 1% | 1% |

Processing Time (at 20°C) | ||||

| At Layer Height 0-3mm | 60min | 120min | 360min | 480min |

| At Layer Height 1cm | 25min | 90min | 360min | 480min |

| At Layer Height 2cm | X | 60min | 360min | 480min |

| At Layer Height 5cm | X | X | 240min | 360min |

| At Layer Height 10cm | X | X | X | 360min |

Technical Properties | ||||

| Touchable / Accessible after | 24h | 24h | 48-72h | 96h |

| Completely Chemically Cured after | 7 days | 7 days | 14 days | 14 days |

| Transparent Resin | ✓ | ✓ | ✓ | ✓ |

| Crystal Clear Curing | X | ✓ | X (ECO+) ✓ (PRO+) | X (ECO M) ✓ (PRO M) |

| Max. Possible UV Stabilisation3 | X | ✓ | X (ECO+) ✓ (PRO+) | X (ECO M) ✓ (PRO M) |

| Self-Venting | ✓ | ✓ | ✓ | ✓ |

| Bubble Free | ✓ | ✓ | ✓ | ✓ |

| Self-Leveling | ✓ | ✓ | ✓ | ✓ |

| Solvent-Free | ✓ | ✓ | ✓ | ✓ |

| VOC Free4 | X | ✓ | X (ECO+) ✓ (PRO+) | X (ECO M) ✓ (PRO M) |

| BPA Free5 | ✓ | ✓ | ✓ | ✓ |

| Plasticiser Free (Phthalate) | ✓ | ✓ | ✓ | ✓ |

| Resistant to Chemicals | ✓ | ✓ | ✓ | ✓ |

| Scratch Resistant6 | ✓ | ✓ | ✓ | ✓ |

| Doming Effect (Depth Effect) | ✓ | ✓ | ✓ | ✓ |

| Miscible with all EPODEX Colours (Except WB PIGMENT) | ✓ | ✓ | ✓ | ✓ |

| Suitable for Underfloor Heating | ✓ | ✓ | ✓ | ✓ |

| Suitable for Outdoor Use | X | ✓ | X (ECO+) ✓ (PRO+) | X (ECO M) ✓ (PRO M) |

| High Adhesion | ✓ | ✓ | ✓ | ✓ |

| Density (g/cm)3 | 1.1 | 1.1 | 1.1 | 1.1 |

| Viscosity (mPa·s) | 700 | 530 | 350 | 350 |

| Max. Heat Deflection Temperature7 | 60°C | 60°C | 60°C | 60°C |

| Min. Heat Deflection Temperature | -30°C | -30°C | -30°C | -30°C |

| SHORE Hardness after Curing (D1) | 87 | 82 | 80 | 80 |

| Storage Temperature | 10-30°C | 15-30°C | 15-30°C | 15-30°C |

| Shelf Life | 12 Months | 12 Months | 12 Months | 12 Months |

| Shelf Life after Opening8 | 6 Months | 6 Months | 6 Months | 6 Months |

- Casting above the maximum pouring height per process is not recommended. The resin may boil as a result of the reaction and yellowing, cracking and deformation can occur. By reducing the temperature (room, substrate, material temperature to e.g. 15 °C and reducing the area to e.g. 15x15cm, casting heights of up to 50cm can be achieved in one casting process

- There is no maximum time limit to pour the next layer.

- No epoxy resin is completely UV stabilised. However, high-quality raw materials and additives such as UV absorbers can increase UV protection. By using a top coat, you can increase UV stabilisation even further. Possible top coats are e.g. transparent polyurethane (PU) resins or lacquers which are painted or sprayed onto the epoxy coating as a finish.

- When properly used and completely cured, it is VOC free..

- According to formula without free BPA.

- Our epoxy resin systems have a high scratch resistance, but are not completely scratch-resistant. Scratch resistance can be increased by using a top coat. Possible top coats are e.g. transparent polyurethane (PU) resins or lacquers which are painted or sprayed onto the epoxy coating as a finish.

- The heat deflection temperature indicates up to which temperature the cured epoxy resin system remains mechanically stable. At higher temperatures, the cured epoxy can soften. By annealing (curing at higher temperatures >60°C), the heat resistance can be increased.

- If the lid of the container is closed directly after opening, the shelf life after opening is at least 6 months.

1. Select colour

2. Quantity of epoxy resin (Resin A + Hardener B)

Exceptional quality - directly from the manufacturer!

With our premium epoxy resin, PRO MAX you can reach high and realise pours up to 10cm height in one pouring process. Pour large river tables, lamps, and other tall projects in no time.

100% safe epoxy resins

Play it safe with your health! EPODEX epoxy resins are non-toxic (according to GHS06) and not hazardous to health (according to GHS08) according to the hazardous substance legislation of the EU and Switzerland. Our high-quality epoxy resins are 100% solvent-free and, according to the formulation, do not contain any free bisphenol A (i.e., BPA-free), which is harmful to health. This guarantees pleasant processing.

No. 1 casting resin with bubble-free curing

No more annoying air bubbles and unevenness! Our epoxy resins self-vent at room temperature. This means that all air bubbles caused by mixing and pouring disappear on their own before the epoxy cures. You do not need a heat gun to remove the bubbles. This means that there is no risk of soot stains on your epoxy resin.

Crystal clear & UV stabilised

Don't compromise and choose the clearest epoxy resin on the market. Get a *money-back guarantee now: If you find a resin that is clearer than our PRO MAX epoxy, we'll give you your money back! (*valid up to 30 days after order). Our PRO MAX epoxy resin also offers the maximum possible UV protection. In this way, we effectively counteract the UV-induced yellowing of the casting resin.

EPODEX - PRO MAX System (Resin+Hardener)

The epoxy PRO MAX system is suitable for a wide range of applications. It is our high-quality casting resin designed to make river tables and other large items. The PRO MAX system is miscible with all our colour pigment.

Instructions for use

- Always start with an epoxy resin primer to avoid high material loss and blistering (layer thickness: 0,2-0,5mm). To do so, simply use a portion of the same clear epoxy resin. Mix the resin A-component with the hardener B-component in a ratio of 2:1 (e.g. 2kg resin: 1kg hardener).

- Stir through the edge and bottom of the mixing cup as the material will settle there. Ideally, pour into a clean mixing cup and mix again until the mixture is streak-free. This ensures that the resin A-component and hardener B-component are completely mixed together.

- Pour the resin-hardener mixture onto the surface to be coated immediately after mixing, as the product may boil in the mixing cup depending on the system and the amount of substance.

- Paint the epoxy primer with a paint roller or brush on the desired surface. Let the primer cure.

- Continue with the main coating in the same way. Processing times, pouring heights and curing times vary depending on the epoxy resin system selected and the application. You can find more detailed information in our information table under the info button "Learn more" on this page.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely (at least 7 days). For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 20°C) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption volumes

Determine the required amount with the help of our epoxy resin "Epoxy calculator" on this page.

Recommended amount of colouring agent per kg of resin+hardener:

- Powder pigments (Metallic, Neon and Glow in the dark): 1,5% (15g),

- Transparent dyes (except white and grey): 60 drops (1,8g),

- Transparent white and grey dyes: 20 drops dye (0,6g),

- Semi-transparent dyes (except white): 40 drops (1,2g) of the desired colour and 20 drops (0,6g) of white dye,

- Semi-transparent white: 60 drops of white dye (1,8g),

- RAL solid colour: 1% (10g),

- Glitter pigments: 1% (10g)

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colours may not be uniformly displayed.

Reviews

Warning Danger

Warning Danger Causes skin irritation. May cause an allergic skin reaction. Causes serious eye damage. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. Harmful if swallowed or in contact with skin. The information on the product label must always be followed.