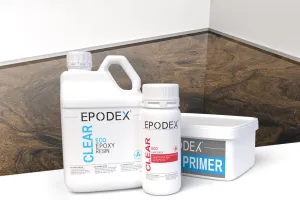

Epoxy Resin for Floor Coatings

Shop epoxy resin design floors, garages (garage sealers), basement floors, stone carpets, industrial and warehouse floors, etc.

- Can be used on all surfaces such as concrete, screed, wood and more

- Layer thickness: approx. 1,5mm

- Working time: approx. 120min.

- Curing time: approx. 24h

- Application instructions can be found on this product page

Please make your selection in the following order.

1. Select colour

2. Quantity of epoxy resin (Resin A + Hardener B)

Please make your selection in the following order.

| ✓ Ideally suited. | X Not suited. | ~ Not ideal, but can be used. |

| ECO System | |

|---|---|

| Mixing ratio by weight Resin (A): Hardener (B) | 100:50 |

Applications | |

| Coating | ✓ |

| Sealing | ✓ |

| Pouring | ✓ |

| Repairing | ✓ |

Application areas (e.g.) | |

| Priming, coating and sealing of floors (industrial floors, garages, interior floors, bath etc.) | ✓ |

| Coating and sealing of tables, countertops and other furnitures/objects | ✓ |

| Bonding and sealing of concrete, wood, plastic, hard foam, natural stone, fiberglass and other materials | ✓ |

Processing caracteristics | |

| Sandable | ✓ |

| Polishable | ✓ |

| Max. Pouring height per process at 20°1 | 1cm |

| Waiting time until further casting at 20°2 (Number of pourings: unlimited) | min. 6h |

| Gelling time and pot life (Gel Timer TECAM) | 25min. (100g) |

| Min. Processing temperature | 15°C |

| Max. processing temperature at max. casting height | 20°C (1cm) |

| Max. processing temperature at 1mm coating height | 35°C |

| Max. relative humidity during processing | 70% |

| Max. Material shrinkage after processing | 1% |

Processing time (at 20°C) | |

| At layer height 0-3mm | 60min. |

| At layer height 1cm | 25min. |

| At layer height 2cm | X |

Touchable / Accessible on foot / Demoldable (at 20°C) | |

| At layer height 0-3mm | after 20h |

| At layer height 1cm | after 20h |

| At layer height 2cm | X |

| Completely chemical curing | after 7 days |

Technical properties | |

| Transparent resin | ✓ |

| Crystal clear curing | X |

| Max. possible UV protection3 | X |

| Self-venting | ✓ |

| Bubble free | ✓ |

| Self-leveling | ✓ |

| Solvent-free | ✓ |

| VOC free4 | X |

| BPA free5 | ✓ |

| Plasticizer free (Phthalate) | ✓ |

| Resistant to chemicals | ✓ |

| Scratch resistant6 | ✓ |

| Doming effect (depth effect) | ✓ |

| Miscible with all EPODEX colors (except WB PIGMENT) | ✓ |

| Suitable for underfloor heating | ✓ |

| Suitable for outdoor use | X |

| High adhesion | ✓ |

| Density (g/cm3) | 1,1 |

| Viscosity (mPa·s) | 700 |

| Max. heat deflection temperature7 | 60°C |

| Min. heat deflection temperature | -30°C |

| SHORE hardness after curing (D1) | 87 |

| Storage temperature | 10-30°C |

| Shelf life | 12 months |

| Shelf life after opening8 | 6 months |

- Coating above the maximum pouring height per process is not recommended. The resin may boil as a result of the reaction and yellowing, cracking and deformation can occur.

- There is no maximum time limit to pour the next layer.

- No epoxy resin is completely UV resistant. However, high-quality raw materials and additives such as UV absorbers can increase UV protection. By using a topcoat, you can increase UV resistance even further. Possible topcoats are e.g. transparent polyurethane (PU) resins or lacquers which are painted or sprayed onto the epoxy coating as a finish.

- When properly used and completely cured, it is VOC free.

- According to formula without free BPA.

- Our epoxy resin systems have a high scratch resistance, but are not completely scratch-resistant. Scratch resistance can be increased by using a topcoat. Possible topcoats are e.g. transparent polyurethane (PU) resins or lacquers which are painted or sprayed onto the epoxy coating as a finish.

- The heat deflection temperature indicates up to which temperature the cured epoxy resin system remains mechanically stable. At higher temperatures, the cured epoxy can soften. By annealing (curing at higher temperatures >60°C), the heat resistance can be increased.

- If the lid of the container is closed directly after opening, the shelf life after opening is at least 6 months.

1. Select colour

2. Quantity of epoxy resin (Resin A + Hardener B)

PU Sealer for Epoxy resin (Optional):

Design flooring & epoxy resin floor sealants

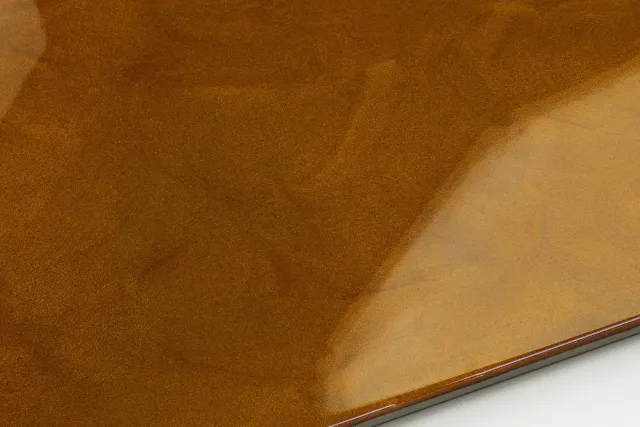

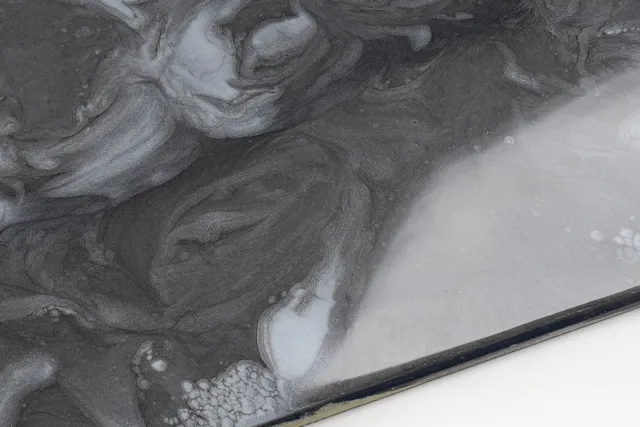

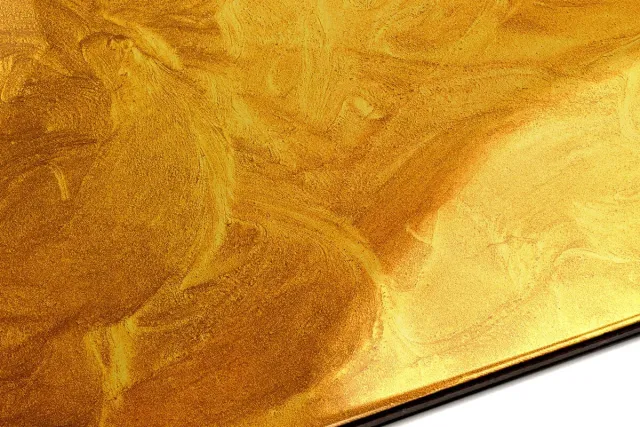

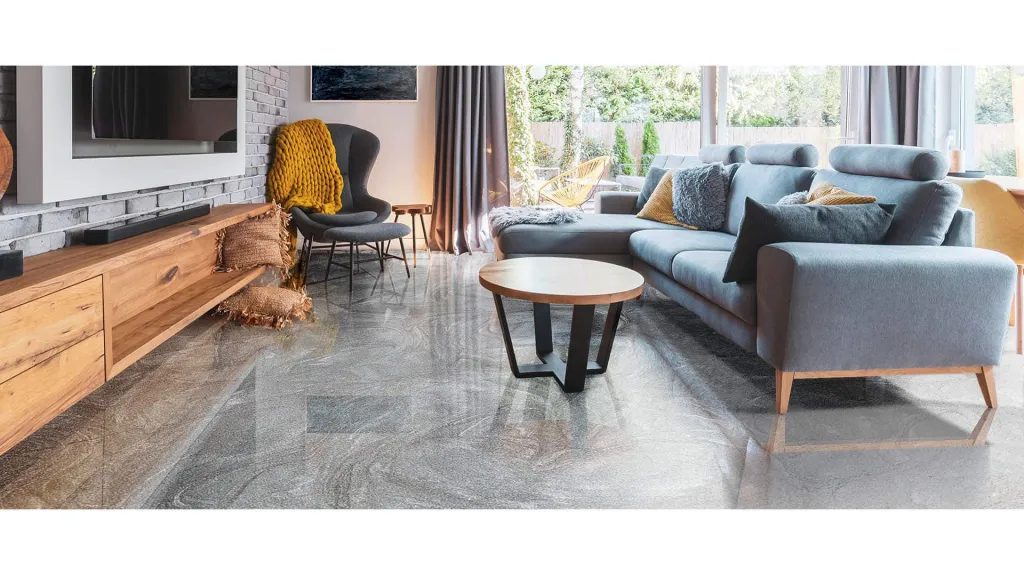

With our two-component epoxy resin sets for floors, you are always on the safe side. No matter whether it's a design floor or a classic floor seal for cellars and garages. Conveniently select your desired colour, determine the squareness and off you go! Get unique stone, marble and granite looks and save money compared to real marble stone. What are you waiting for? - Give your home a unique look!

100% safe epoxy resins –

Play it safe with your health! EPODEX epoxy resins are non-toxic (according to GHS06) and non-hazardous to health (according to GHS08) according to the hazardous substance legislation of the EU and Switzerland. Our high-quality epoxy resins are 100% solvent-free and, according to the formulation, do not contain any free bisphenol A (i.e., BPA-free), which is harmful to health. This guarantees pleasant processing.

No. 1 coating resin with bubble-free curing

Our epoxy resins self-vent at room temperature. This means that any air bubbles created by mixing and pouring will disappear on their own before the epoxy cures. Thanks to our unique formula, you do not need a spiked deaeration roller or other equipment to remove the bubbles.

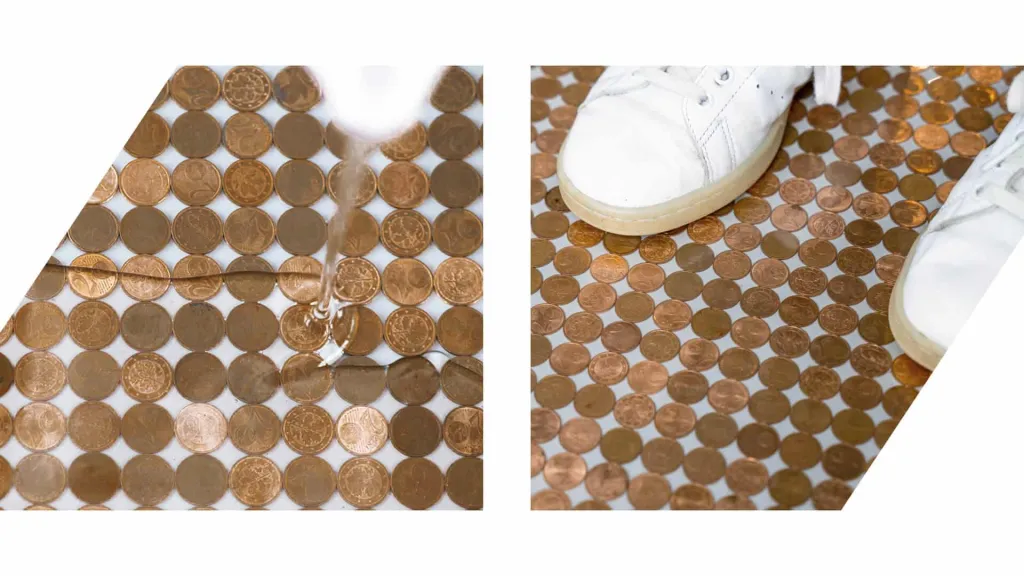

Cast 3D Pennyfloor yourself!

You want to cast a 3D floor? No problem, our clear epoxy resin set allows you to create a crystal-clear coating! Pour in coins and other things and wow your friends and guests with an absolute eye-catcher!

Reviews

Warning Danger

Warning Danger Causes severe skin burns and eye damage. Causes skin irritation. May cause an allergic skin reaction. Causes serious eye irritation. Harmful if inhaled. Toxic to aquatic life with long lasting effects. Harmful to aquatic life with long lasting effects. Contains epoxy constituents. May produce an allergic reaction. Harmful if inhaled. May cause respiratory irritation. Contains isocyanates. The information on the product label must always be followed.