Epoxy Mortar for Repair Jobs & More

Epoxy mortar is a mixture of epoxy resin and quartz sand. In the epoxy flooring industry, one of the most commonly used minerals is quartz sand. Quartz is a notoriously hard mineral with life-long durability making it ideal for industrial floors. It can also be used in repairs jobs such as renovations and building trade. You can use epoxy mortar to mend gaps, holes, and cracks, in concrete and screed and for various other assembly work.

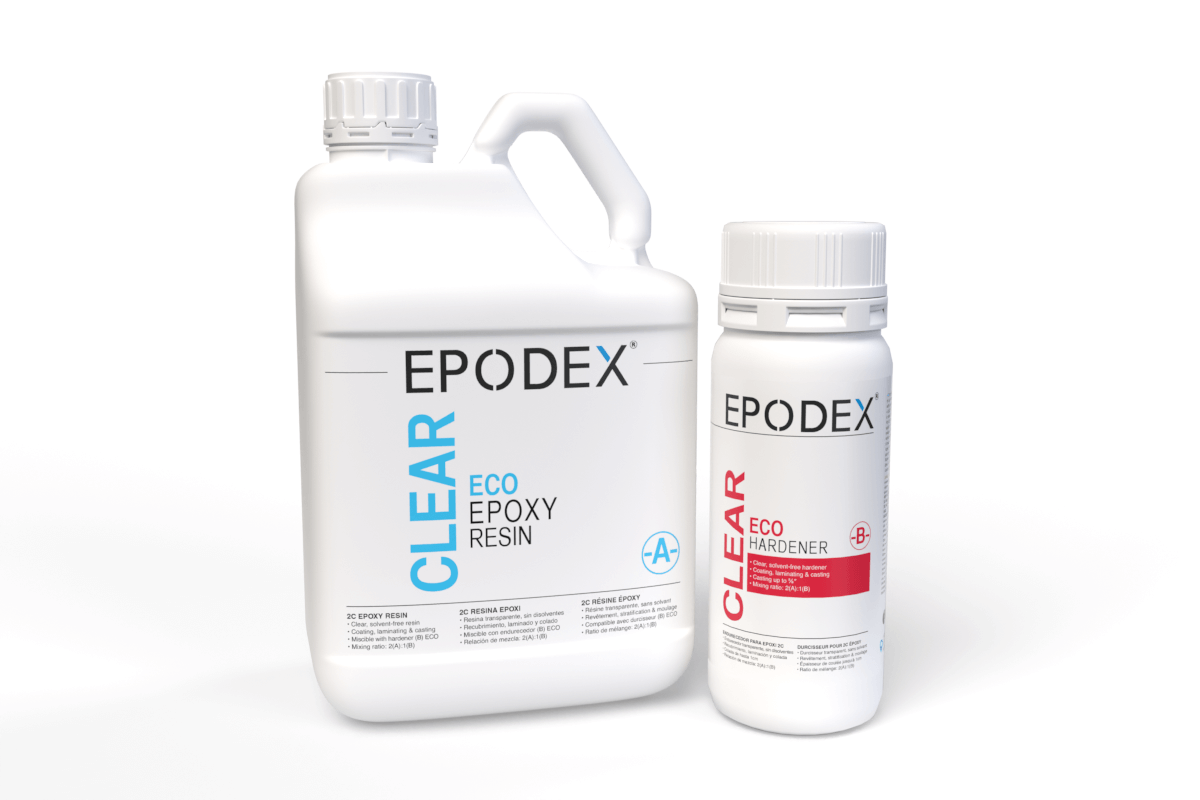

Epoxy mortar can be self-produced. You will need our EPODEX ECO system and quartz sand that should be mixed together in the correct ratio.

- Resin to coat, laminate and repair

- Application: Casting and Laminating

- Layer thickness: 0,1-1cm

- Clear, frost stable and BPA-free

- Use: Coating (floor, table etc.), making of terrarium/aquarium, stone carpet, jewellery making and much more

Epoxy Mortar vs Cement Mortar

Cement mortar is one of the best known and most frequently used types of mortar. However, epoxy mortar has numerous advantages over cement mortar. Epoxy mortar can be used to coat mechanically stressed areas (e.g. surfaces that are subject to traffic) or uneven surfaces in the millimetre range. Cement mortar, on the other hand, would flake off or crumble in a short amount of time when exposed to mechanical stress.

When properly applied and cured, epoxy repair mortar is characterized by high chemical resistance to de-icing salt solutions, oils, greases, fuels and to a large number of mineral and diluted acids. In terms of processing, there is generally no difference between the two types of mortar.

Mixing Epoxy Repair Mortar

You can easily mix epoxy repair mortar yourself. All you need is our solvent-free ECO epoxy resin, which you then mix with eight to ten parts of an absolutely dry quartz sand mixture. You can obtain this at a reasonable price from your local hardware store. The sand mixture ideally consists of 50% grit (0.4 to 0.8 millimetres) and the other half of sand aggregate (0.2 to 2 millimetres). Due to the heavyweight of quartz sand, we recommend ordering small quantities when shopping online as shipping costs will increase.

You will achieve the best results when working with two vats. First, mix half of the epoxy resin to be used according to the instructions. Mix resin and hardener in a large jug and stir them together for a few minutes. Then, add half of the quartz sand and mix it with a drilling machine or mixer. In the second vat, you must stir the rest of the epoxy resin and gradually add it to the mixture with the remaining quartz sand. Make sure to clean your tools thoroughly after use with a thinner.

More than

1000000+

Satisfied customers

How-To Apply Epoxy Repair Mortar

It is advisable to observe the necessary safety measures when working with the products mentioned above. You should always wear gloves and a dust mask to protect yourself.

Before you start working with the epoxy repair mortar, pay close attention to its pot life and apply it immediately after mixing. You have approximately 25 minutes to do this. The mortar then begins to slowly cure and the application becomes harder and harder. Apply the mortar with oscillating/brushing movements using a trowel.

You can apply a maximum layer of 1cm per coating. If you wish to apply for a second coat, you must wait 6 hours to do so. After 20 hours the epoxy mortar is firm and accessible by foot. Please be advised that it takes 7 days until it’s fully cured.